- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 118 Author: Site Editor Publish Time: 2026-01-29 Origin: Site

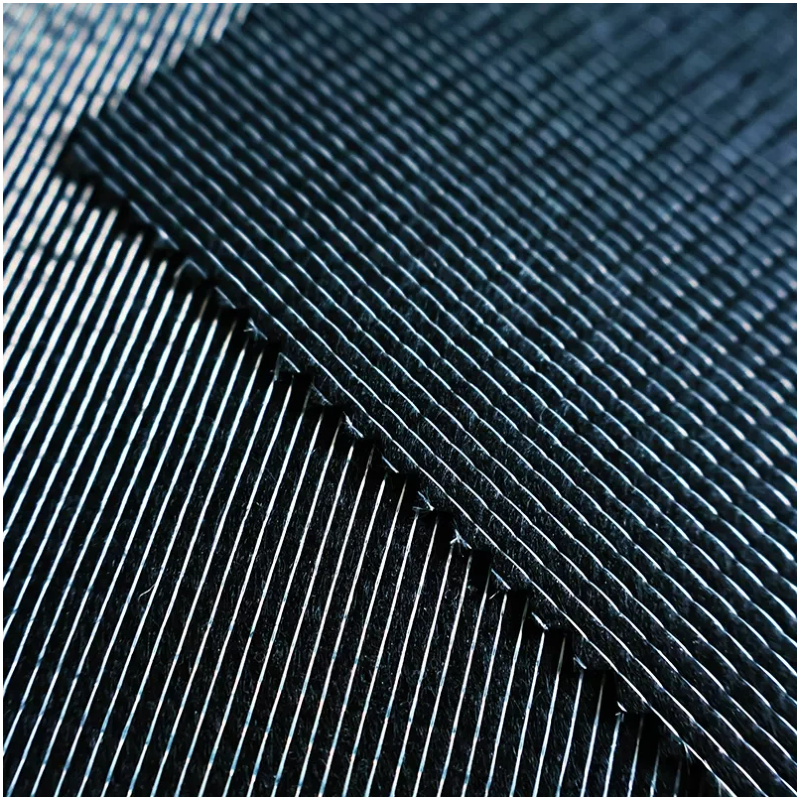

Material choices quietly shape how modern industries perform every day, affecting efficiency, safety, and long-term cost control across supply chains. That is why PP woven Cloth has become one of the most widely adopted materials in industrial environments worldwide. It combines strength, flexibility, and repeat usability in a way few alternatives can match. Yet many businesses still seek clarity on where PP woven Cloth is actually used and why it continues to outperform other materials. In this article, you will explore the most common real-world applications of PP woven Cloth across key industries. Each section explains how its performance characteristics translate into practical value for manufacturers, distributors, and end users.

Bulk industrial materials place very different stresses on packaging depending on density, flow behavior, and environmental exposure. PP woven Cloth is adjusted through GSM, weave density, and liner configuration to meet these specific demands. The table below shows how specifications change by material type.

| Material Type | Common Bag Style | Recommended GSM | Tensile Strength (Warp / Weft) | Weave Density (Ends × Picks) | Inner Liner Needed | Key Technical Focus |

|---|---|---|---|---|---|---|

| Cement | Valve bag | 95–110 | ≥ 650 / 600 N (5 cm) | 10×10 – 12×12 | Yes | Moisture resistance, dust containment |

| Fertilizer | Open-mouth bag | 80–100 | ≥ 600 / 550 N | 9×9 – 11×11 | Optional | Chemical resistance |

| Grains | Sewn bag | 70–90 | ≥ 500 / 480 N | 8×8 – 10×10 | No | Breathability balance |

| Chemical powders | Heat-sealed bag | 100–120 | ≥ 700 / 650 N | 12×12 | Yes | Abrasion resistance, anti-static control |

Tip: For high-density powders, prioritize weave density over GSM alone to reduce seam stress.

FIBC jumbo bags depend heavily on PP woven Cloth to move large quantities of dry bulk materials efficiently. These bags are designed to carry significant loads, often exceeding hundreds of kilograms, and the woven fabric ensures load stability during lifting and transport. PP woven Cloth supports reinforced seams, lifting loops, and optional liners without compromising strength. Logistics operators rely on this material because it allows safe crane and forklift handling while maintaining bag integrity. Its balance of strength and weight makes it ideal for large-scale industrial logistics and bulk material distribution.

In retail and export markets, packaging must protect products while also supporting brand presentation. PP woven Cloth combined with BOPP lamination achieves this balance effectively. The woven base provides mechanical strength, while the laminated surface improves moisture resistance and print quality. This makes it suitable for food products, pet feed, seeds, and specialty goods. Exporters favor these bags because they perform reliably under varying humidity conditions during shipping. The result is packaging that maintains visual appeal, reduces damage claims, and supports consistent branding across international markets.

Food and agricultural produce packaging requires a material that is both strong and breathable. PP woven Cloth meets this requirement by allowing controlled air circulation while maintaining structural stability. This helps reduce condensation and supports freshness when packaging rice, flour, sugar, maize, and animal feed. The fabric also withstands repeated handling during storage and transport without deformation. Food processors value this consistency because it supports standardized filling weights and clean logistics. Over time, the durability of PP woven Cloth contributes to lower spoilage rates and more predictable supply chain performance.

Agriculture depends on reliable storage solutions, and PP woven Cloth plays a central role in grain, seed, and crop storage. The fabric provides enough strength to support heavy stacking while allowing airflow that helps maintain internal conditions. This combination reduces moisture buildup during storage and transport. Farmers and distributors rely on PP woven Cloth bags for seasonal storage because they perform consistently across temperature changes. The durability of the material also supports multiple reuse cycles, helping agricultural operations reduce costs while protecting crop value before it reaches the market.

Weed control fabrics made from PP woven Cloth are widely used in agriculture and landscaping to improve soil management. These ground covers block sunlight to suppress weed growth while allowing water and nutrients to pass through. The woven structure ensures durability even when exposed to outdoor conditions over extended periods. Farmers benefit from reduced labor associated with manual weed removal and more uniform crop growth. Over time, PP woven Cloth ground covers help maintain cleaner fields and support more efficient planting and harvesting operations.

Crop protection often involves controlling sunlight, wind, and environmental exposure. PP woven Cloth shade materials help regulate light intensity while maintaining airflow around plants. This improves growing conditions during peak heat periods and reduces crop stress. The fabric’s strength supports large-span installations without sagging or tearing. Farmers value its durability across multiple growing seasons. By providing consistent protection, PP woven Cloth shade solutions contribute to improved crop quality and more predictable yields in controlled agricultural environments.

Handling fertilizers and agricultural inputs at scale requires packaging that combines strength and efficiency. PP woven Cloth bulk bags are well suited for this purpose because they handle heavy loads while remaining easy to transport. Their structure supports mechanized filling and discharge systems, improving workflow efficiency. Agricultural suppliers rely on these bags to distribute inputs reliably to farms. The ability to integrate liners also helps protect moisture-sensitive materials. Overall, PP woven Cloth simplifies logistics in agricultural supply chains.

Sandbags made from PP woven Cloth are widely used in construction and flood control applications. The fabric holds sand securely and maintains shape when stacked, forming effective barriers against water and debris. Construction teams rely on these sandbags for temporary site protection and emergency response. Their durability allows reuse across multiple projects. The strength of PP woven Cloth ensures dependable performance during high-pressure situations, making it a standard material for site safety and environmental protection.

In civil engineering projects, material performance must be predictable under continuous load, moisture variation, and long service cycles. PP woven Cloth is widely specified as a geotextile because its tensile strength and elongation characteristics can be engineered with precision. Different infrastructure layers—such as road bases, embankments, and parking areas—experience very different stress distributions. Selecting the correct fabric weight and mechanical profile is critical to prevent settlement, deformation, or uneven load transfer. The following table summarizes commonly used specification ranges that engineers rely on when designing soil stabilization systems with PP woven Cloth.

| Application Area | Recommended GSM | Tensile Strength (MD/CD) | Elongation at Break | Primary Structural Role |

|---|---|---|---|---|

| Road base | 150–180 | ≥ 20 kN/m | ≤ 15% | Controls settlement and improves load spread |

| Embankments | 180–250 | ≥ 25 kN/m | ≤ 12% | Reinforces slope stability and resists lateral movement |

| Parking areas | 140–160 | ≥ 18 kN/m | ≤ 18% | Distributes vehicle loads and reduces rutting |

Tip: For long-term infrastructure exposed to traffic or water flow, prioritize lower elongation values over higher GSM alone, as controlled deformation is more critical than thickness.

Erosion control requires materials that balance filtration and soil retention. PP woven Cloth supports these needs by allowing water flow while holding soil in place. It is commonly used in drainage systems, slopes, and embankments. The fabric performs reliably under continuous exposure to water and environmental forces. Civil projects benefit from reduced maintenance and improved terrain stability. PP woven Cloth plays a quiet but essential role in supporting long-term infrastructure performance.

In bulk logistics, material performance is measured by consistency under repeated stress rather than peak strength alone. PP woven Cloth bulk transport bags are typically produced in the 80–130 GSM range, allowing safe handling of 25–50 kg per bag in dry-goods applications. The woven structure limits elongation during stacking, which helps maintain pallet stability during long-distance transport. Low fabric weight reduces overall shipment mass, contributing to fuel efficiency and lower freight costs. These bags also perform reliably in automated handling systems, supporting standardized logistics workflows across road, rail, and container transport.

Industrial products such as lumber, metal components, and machinery require surface protection during transit. PP woven Cloth wrapping shields these goods from dust, abrasion, and minor impacts. The fabric adapts to irregular shapes without losing strength. Transport teams value its ease of application and removal. By maintaining product condition during shipping, PP woven Cloth supports smoother logistics and fewer handling issues.

High-throughput warehouses require packaging that maintains shape and strength under constant movement. PP woven Cloth supports palletized storage by resisting creep and deformation under sustained loads. Bags made from 90–120 GSM fabric retain dimensional stability during stacking, reducing the risk of pallet collapse. This stability improves storage density and aisle safety. The woven structure also tolerates repeated lifting, sliding, and repositioning, making it suitable for automated and manual handling systems. By reducing handling failures, PP woven Cloth contributes to smoother material flow and more predictable warehouse operations.

In manufacturing environments, protective covers must balance barrier performance with ease of use. PP woven Cloth is commonly selected in the 80–130 GSM range, providing sufficient mechanical strength while remaining lightweight for frequent installation and removal. Its low moisture absorption rate (typically <5%) helps limit condensation on equipment surfaces, reducing corrosion risk. The woven structure also resists tearing when dragged across sharp edges or fasteners. By using standardized PP woven Cloth covers, factories can reduce cleaning downtime, protect precision components, and maintain equipment readiness across continuous production cycles.

For filtration and separation tasks, material behavior must be predictable under constant flow and load. PP woven Cloth offers controlled pore spacing determined by weave density, allowing consistent permeability while maintaining structural integrity. This makes it suitable for applications such as solid–liquid separation, bulk material liners, and protective process layers. Typical fabrics operate within 8×8 to 12×12 weave densities, balancing flow rate and retention. Its chemical resistance supports use with a wide range of industrial materials, enabling stable process performance and reduced variability in filtration or lining systems.

Internal factory logistics prioritize repeatability, safety, and low handling effort. PP woven Cloth bags and covers are widely used because their high strength-to-weight ratio supports frequent lifting without excessive operator fatigue. Fabrics in the 90–120 GSM range can withstand hundreds of handling cycles while maintaining dimensional stability. Low elongation helps bags retain shape, improving stacking and identification during in-process storage. By standardizing on PP woven Cloth for internal handling, factories simplify material flow, reduce packaging failure, and support lean manufacturing systems with predictable daily operations.

From a product-engineering perspective, reusable bags made from PP woven Cloth are designed around load cycles rather than single use. Most retail-grade bags use 80–100 GSM fabric, which safely supports 15–25 kg without permanent deformation. The woven structure provides dimensional stability, so bags recover their shape after repeated loading. For branding, PP woven Cloth offers a flat, printable surface that maintains color clarity over long use periods. This combination allows retailers to treat bags as long-term advertising assets rather than disposable packaging.

In furniture manufacturing, PP woven Cloth functions as a structural support layer rather than a visible textile. It is typically used in the 70–120 GSM range, providing reinforcement without adding bulk or stiffness. The fabric stabilizes cushions, seat bases, and upholstery panels by limiting stretch under constant load. Its abrasion resistance helps prevent internal wear caused by repeated movement. Because PP woven Cloth maintains uniform quality and thickness, it integrates easily into automated upholstery processes, supporting consistent product performance over long furniture life cycles.

Household storage products demand materials that tolerate repeated handling, folding, and load variation. PP woven Cloth meets these needs through high tear resistance and low creep under sustained weight. Storage bags commonly use 90–120 GSM fabric, enabling them to hold 20–40 kg without seam failure. The material’s smooth surface limits dirt adhesion and allows easy cleaning, which extends usable life. By resisting deformation during stacking or transport, PP woven Cloth supports organized storage while reducing the need for frequent replacement.

In flood emergencies, materials must perform immediately after storage and under intense water pressure. PP woven Cloth sandbags are widely adopted because they balance strength, handling speed, and durability, making them suitable for rapid-response public safety operations.

| Application Context | Typical Deployment Scenario | PP Woven Cloth Technical Specifications | Key Performance Indicators | Operational Advantages | Practical Usage Notes |

|---|---|---|---|---|---|

| Urban flood control | Temporary barriers along streets and buildings | Fabric weight: 120–140 GSM; Weave density: ≥ 12×12 ends/inch | Tensile strength: ≥ 700 N/5 cm; Seam strength: ≥ 75% of fabric | Maintains bag shape under lateral water pressure | Ensure uniform filling to avoid weak stacking points |

| Riverbank and canal protection | Reinforcement during rising water levels | UV-stabilized PP woven Cloth (1–2% UV additive) | Tear resistance: ≥ 20 N; Elongation ≤ 12% | Resists abrasion from debris and flowing water | Double stitching recommended for extended use |

| Emergency response stockpiles | Long-term storage for disaster preparedness | Low water absorption PP woven Cloth (≤ 5%) | Shelf life: ≥ 3 years under dry storage | Retains mechanical strength after prolonged storage | Store in ventilated, shaded conditions |

| Construction site flood defense | Temporary isolation of active work zones | Medium–high GSM PP woven Cloth (110–130 GSM) | Burst resistance: ≥ 700 N | Allows fast filling and rapid deployment | Compatible with manual and mechanical filling |

| Coastal or storm-surge defense | Exposure to high water pressure and saltwater | Chemically resistant PP woven Cloth | Abrasion resistance: ≥ 150 cycles (Taber, CS-17) | Performs reliably in saline environments | Rinse after use to extend reusability |

Tip: For public safety procurement, specify PP woven Cloth sandbags with verified seam-strength testing and UV stabilization to ensure readiness during sudden deployment, not just storage durability.

In municipal waste systems, PP woven Cloth is selected for its predictable load behavior and resistance to mechanical stress during daily collection cycles. Compared with thin plastic liners, woven structures distribute weight more evenly, reducing rupture when handling mixed or irregular waste. Typical bags use 100–130 GSM fabric, allowing safe loads of 25–50 kg depending on design. Their low elongation helps maintain bag shape during lifting, which lowers spillage risk at transfer points. Many municipalities also favor PP woven Cloth because it tolerates repeated contact with moisture and rough surfaces, improving worker safety and operational continuity in high-frequency waste routes.

Public works projects require materials that perform consistently across varied environments, from road maintenance to utility upgrades. PP woven Cloth is widely used for debris containment, temporary material transport, and protective covering because it combines strength with easy handling. Fabric weights typically range from 90–150 GSM, balancing durability with mobility for field crews. The woven structure resists tearing when dragged or stacked, while optional coatings improve moisture resistance in outdoor tasks. By standardizing on PP woven Cloth, municipal teams simplify procurement, reduce material failure on-site, and maintain predictable logistics across multiple public infrastructure operations.

This article shows how PP woven Cloth supports packaging, agriculture, construction, logistics, and public services through strength and reliability. Its performance enables safer handling, lower losses, and efficient reuse across demanding environments. Companies such as LEEBO Environmental Protection Materials Co., Ltd. deliver PP woven Cloth solutions designed for durability, consistency, and practical industrial value. By combining material expertise with application-focused products, they help businesses improve efficiency and long-term operational stability.

A: PP woven Cloth is widely used in packaging, agriculture, logistics, and construction.

A: PP woven Cloth offers high strength, light weight, and reliable reuse.

A: PP woven Cloth supports crop storage, ground covers, and fertilizer transport.

A: PP woven Cloth handles stacking, lifting, and long-distance transport efficiently.

A: PP woven Cloth provides better durability, load stability, and reuse cycles.

A: PP woven Cloth lowers costs through reuse, reduced damage, and longer service life.

content is empty!