- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 22 Author: Site Editor Publish Time: 2025-12-05 Origin: Site

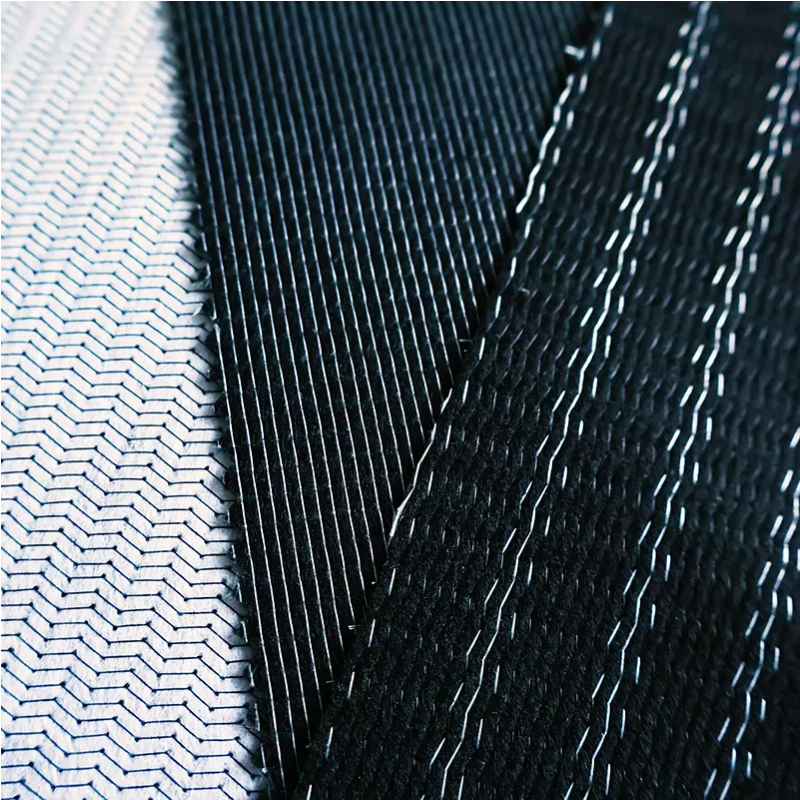

Stitchbonded fabric has increasingly become a go-to material for home textile manufacturers and interior designers seeking a perfect combination of performance, durability, and eco-conscious design. Unlike traditional woven fabrics, stitchbonded materials integrate the soft tactile qualities of textiles with the structural functionality of nonwoven fabrics, creating versatile options that cater to both aesthetic and functional needs. From mattress comfort layers to upholstery backing, decorative cushions, curtains, and even carpet underlays, this material allows designers and product developers to achieve enhanced comfort, stability, and longevity in home furnishings. LEEBO, a leading manufacturer of stitchbonded fabrics since 2002, has leveraged its extensive research and production experience to provide premium quality fabrics suitable for a wide range of home applications, helping brands elevate both product performance and consumer perception.

As sustainability and functional design increasingly drive purchasing decisions in the home textile market, stitchbonded fabrics emerge not only as durable and cost-efficient choices but also as materials that align with modern eco-conscious consumer values. By integrating recycled polyester into the production process, LEEBO has developed fabrics that significantly reduce environmental impact while maintaining the highest standards of quality, resilience, and aesthetic appeal.

Stitchbonded fabric’s versatility makes it uniquely suited for multiple home applications. Its construction provides structural stability while maintaining softness and flexibility, making it ideal for products that require both comfort and durability. This section explores the most common home textile applications and how stitchbonded fabrics enhance each one.

In mattress production, stitchbonded fabrics function as both comfort-enhancing layers and supportive cores. Their ability to distribute weight evenly helps prevent sagging and ensures consistent comfort throughout the mattress’s service life. The material’s inherent resilience reduces the compression of foam layers, while the breathable structure enhances air circulation, preventing moisture accumulation and improving sleep hygiene.

For upholstery backing, stitchbonded fabric provides a stable foundation that supports decorative fabrics and prevents deformation over time. Sofas, chairs, ottomans, and headboards benefit from stitchbonded layers that reduce wrinkling, sagging, and shifting of upholstery materials. Furniture manufacturers often select heavier grades of stitchbonded fabric to ensure that upholstered items maintain their shape and structural integrity, even under heavy use in family or commercial settings.

Beyond functional support, stitchbonded fabrics enhance the aesthetic and tactile quality of home décor. For curtains, the material adds drape stability while reducing creases and fabric movement. Its compatibility with lamination and coating processes allows for features such as water repellency or UV protection, which are increasingly desired in contemporary home design.

Cushions and decorative pillows gain significant benefits from stitchbonded fabric, which provides both softness and resilience. Unlike traditional padding, stitchbonded inserts retain their shape after repeated use, enhancing the perceived quality and comfort of the product. The material’s versatility also allows it to serve as an intermediate layer in carpet underlays, improving underfoot comfort and extending the life of floor coverings.

In addition to traditional home furnishings, stitchbonded fabrics are increasingly being applied in specialty furniture, such as recliners and modular seating systems, where durability, shape retention, and comfort are critical. Designers also integrate stitchbonded layers into pet furniture, bedding, and outdoor home accessories, leveraging the material’s resistance to abrasion and pilling. These diverse use cases demonstrate the adaptability of stitchbonded fabric in both conventional and innovative home textile applications.

One of the defining attributes of stitchbonded fabrics is their ability to balance tactile softness with structural stability—a quality often referred to as “hand” in textile terminology. This balance is particularly important for applications such as bedding and upholstery, where comfort and durability must coexist.

The fiber composition of stitchbonded fabric plays a critical role in determining its hand. Fabrics with higher recycled polyester content retain a soft and smooth feel while offering the mechanical strength necessary for long-term use. Polyester fibers provide excellent dimensional stability, meaning the fabric resists stretching or shrinking over time. Combining polyester with minor blends of other fibers, such as cotton or viscose, allows for additional softness, breathability, and aesthetic variation, depending on the intended application.

Stitchbonded fabrics are available in various thicknesses and weights, each suited for different applications. Heavier, denser fabrics are ideal for upholstery backing and high-use furniture because they provide structural integrity and resist deformation under repeated stress. Medium-weight fabrics suit cushions and mattress layers, offering a soft yet supportive feel. Lighter-weight versions are perfect for curtains and decorative items where drape, flexibility, and aesthetic flow are more important than compressive resistance. By carefully selecting thickness and density, designers can tailor the hand of stitchbonded fabrics to achieve optimal comfort without compromising performance.

Finishing processes such as brushing, heat-setting, calendering, or embossing further refine the tactile experience of stitchbonded fabrics. Brushing produces a plush, velvety surface that enhances comfort, while heat-setting locks the fabric’s dimensions, preventing stretching or shrinkage. Calendering flattens the material for smoothness, and embossing adds decorative textures without sacrificing structural stability. These finishing techniques allow home textile designers to meet both functional and visual demands, creating products that appeal to discerning consumers.

Durability is a primary consideration for home textile materials, particularly those used in high-traffic areas or furniture subjected to frequent wear. Stitchbonded fabrics are engineered to meet these rigorous demands while maintaining comfort and aesthetic quality.

Stitchbonded fabrics demonstrate excellent resistance to abrasion, making them ideal for sofas, chairs, and mattresses that experience continuous use. Abrasion testing reveals that these fabrics can endure repeated friction without fiber breakage or surface degradation, ensuring the product maintains its original look and feel over time.

Pilling, the formation of small fiber balls on the surface, is a common problem in textiles, especially for high-contact areas. Stitchbonded fabrics are designed to minimize pilling, retaining a smooth surface even after extensive use. The tightly stitched construction prevents fibers from loosening, providing a longer-lasting aesthetic appeal.

Home consumers increasingly expect fabrics to be easy to clean and maintain. Many stitchbonded fabrics are compatible with washing, spot-cleaning, or vacuuming, and can withstand mild cleaning agents without compromising structural integrity. Some grades also accept stain-resistant treatments, which further enhance longevity and reduce the need for frequent replacement. This combination of durability and ease of care is a compelling advantage for manufacturers and consumers alike.

Designers do not have to compromise on aesthetics when selecting stitchbonded fabrics. The material’s compatibility with advanced finishing processes enables the creation of visually appealing, functional products for a wide range of interior styles.

Lamination or coating can add properties such as water resistance, flame retardancy, and UV protection, expanding the practical applications of stitchbonded fabrics. These treatments are especially useful for curtains, outdoor furniture, and mattresses, ensuring that the material performs effectively under diverse conditions.

Digital or rotary printing allows designers to incorporate intricate patterns, color gradients, and textures directly onto stitchbonded fabrics. Embossing adds depth and tactile variety without compromising structural stability. These techniques help brands produce home textiles that stand out visually while maintaining functional performance.

Maintaining color vibrancy over time is critical for consumer satisfaction. Stitchbonded fabrics can be dyed using high-quality processes that resist fading due to washing, sunlight, or general wear. This ensures that furniture, cushions, and curtains retain their intended visual appeal for years, reinforcing product value and brand reputation.

Sustainability is no longer a secondary consideration in home textile manufacturing—it is a central factor influencing purchasing decisions. Stitchbonded fabrics offer a clear advantage in this regard.

LEEBO’s stitchbonded fabrics are composed predominantly of recycled polyester, typically ranging from 80% to 95% of the total fiber content. By diverting post-consumer plastics from landfills and reprocessing them into high-quality fabrics, these materials reduce environmental impact and support circular economy initiatives.

Home brands can leverage stitchbonded fabrics’ sustainable credentials in their marketing, emphasizing reduced resource consumption, recycled content, and durability. This appeals to eco-conscious consumers who are increasingly aware of the environmental impact of their purchasing decisions. By incorporating stitchbonded fabrics into home textiles, brands not only improve their sustainability profile but also enhance perceived product quality, aligning with contemporary consumer values and regulatory expectations.

Selecting the appropriate stitchbonded fabric grade ensures the right balance of comfort, durability, and aesthetic appeal for each application.

For upholstery backing, heavier, denser fabrics are recommended, providing structural support and maintaining fabric alignment under stress. For mattress comfort layers, medium-weight fabrics provide the perfect combination of softness and resilience, enhancing sleep quality and comfort. Lighter-weight grades are ideal for curtains, decorative pillow inserts, and carpet underlays, where flexibility, drape, and subtle support are more important than compressive strength.

Finishing options, including lamination for water resistance, brushing for a plush hand, and heat-setting for dimensional stability, allow brands to customize stitchbonded fabrics to meet functional and visual requirements. By carefully selecting grades and finishes, home textile brands can ensure their products stand out for both quality and aesthetic appeal.

LEEBO continues to lead the market in the production of high-quality stitchbonded fabrics, offering versatile solutions for home textile applications, including mattresses, upholstery, cushions, curtains, and decorative items. With proven durability, excellent tactile qualities, aesthetic flexibility, and sustainability credentials, stitchbonded fabrics help brands create products that meet modern consumer demands while enhancing product longevity and value. For tailored sample packs, technical guidance, and collaboration on home textile applications, please contact us to explore how our stitchbonded materials can elevate your products and design vision.

Q1: Why is stitchbonded fabric ideal for home furniture applications?

A1: Its combination of structural support, softness, and resilience makes it suitable for mattresses, upholstery, and cushions, maintaining shape and comfort over time.

Q2: Can stitchbonded fabrics be tailored for specific home textile needs?

A2: Yes, fiber blends, fabric weight, thickness, and finishing treatments can be customized for optimal performance in different products.

Q3: How does using stitchbonded fabric contribute to sustainability?

A3: Composed mainly of recycled polyester, it reduces environmental impact and enables brands to communicate eco-friendly product benefits to consumers.

Q4: What finishing options enhance stitchbonded fabric performance and appearance?

A4: Lamination, coatings, embossing, digital printing, and heat-setting provide water resistance, flame retardancy, decorative textures, and colorfastness.

content is empty!